Manual dosing and capping monoblocks

Pouchélite

Beverage

Beverage Cosmetic

Cosmetic Food

Food Chemical

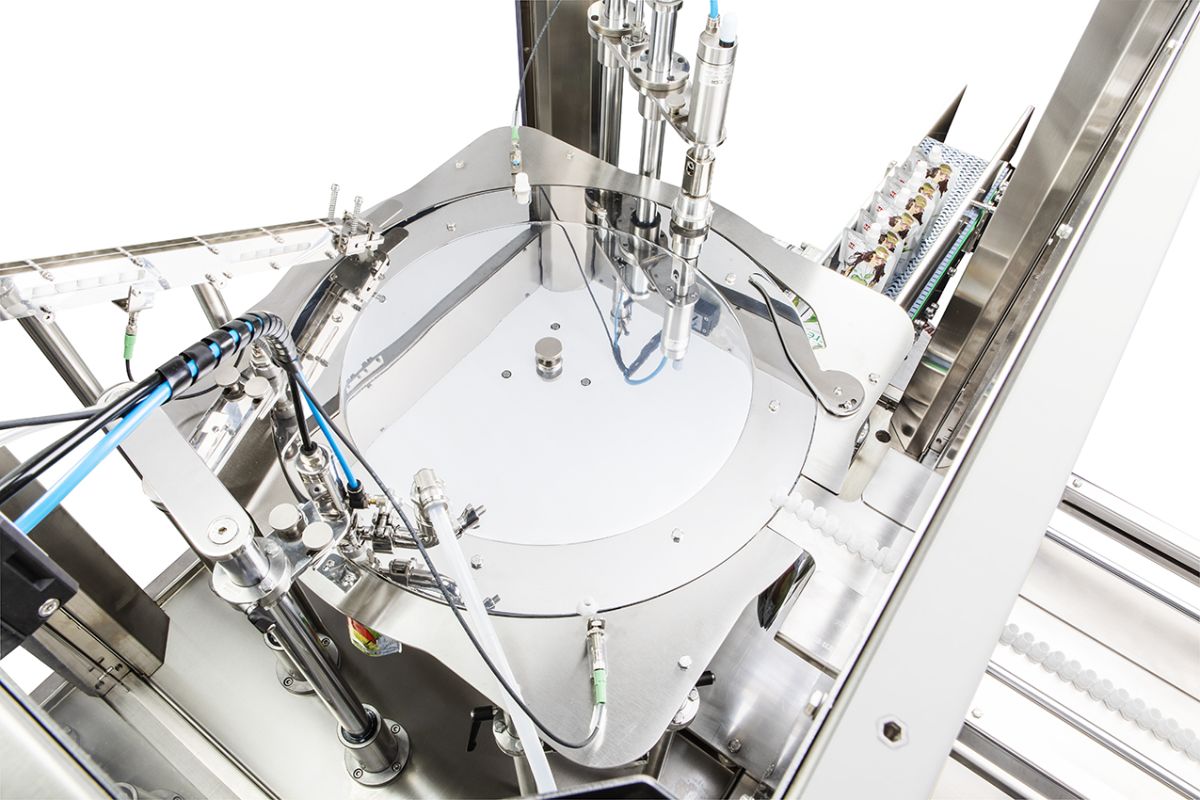

ChemicalSemi-automatic pneumatically operated machine suitable for filling and capping flexible doypack-type bags (with already welded spout) with liquid and/or semi-dense products by means of a Doselite volumetric dosing pump. All parts in contact with the product are made of 316L stainless steel and suitable for contact with food, cosmetics, chemical and pharmaceutical products.

Available with or without inert gas injection before capping to increase product shelf life. The cap is screwed in by an air motor with torque regulation.

This volumetric dosing unit is able to fill even viscous products containing particles or soft fibers of product in suspension and is also suitable for filling at high temperatures.

Technical specifications

Some technical data to know more about Pouchélite

Specifications

- 400 p/h for 250 ml flexible bags

- pneumatics

- 1300 x 550 x 1160H

- 115 kgs

- 300 l/min

Configurations

- Pouchélite 5-250 with nitrogen injection

- Pouchélite 5-250 without nitrogen injection

- Pouchélite 5 - 380 with nitrogen injection

- Pouchélite 5-380 without nitrogen injection

- Pouchélite 20-680 with nitrogen injection

- Pouchélite 20-680 without nitrogen injection

- Pouchélite 50-1300 with nitrogen injection

- Pouchélite 50-1300 without nitrogen injection

- Pouchélite 50-1500 with nitrogen injection

- Pouchélite 50-1500 without nitrogen injection

- Pouchélite 100-5000 with nitrogen injection

- Pouchélite 100-5000 without nitrogen injection

- Conical feed hoppers (from 6 Lt - from 15 Lt to 30 Lt)

- Conical double-walled feed hoppers with mixer and heating (from 15 Lt and 30 Lt)

- Conical feed hoppers with heating band and mixer) (from 15 and 30 Lt )

- Conical hopper with mixer (15 and 30 lt)

- Dosing heating system

- Valve heating system

- Customized stainless steel fork for bag format change

- Stainless steel mandrel for plastic screw cap format change

- Stainless steel mandrel for anti-choking cap format change (babyfood cap)

Packaging

- flexible bags type doypack with spout already welded (lateral or central spout)

- ribbed screw plastic caps

- anti-choking plastic caps (baby caps, wavy caps, baby caps, brick caps, tethered caps)

Video Gallery

To see Pouchélite in action in various versions and for different applications, you can explore our video library.

FAQs

Do you still have any doubts? Here you will find all the answers you need.

Yes, the Pouchélite manual monobloc works with the help of an operator who must insert the bag and start the dosage by pressing a side button and lowering the valve on the spout to start the dosage process. Subsequently, it is necessary to place the cap on the bag and using the side button and by lowering the lever, it is possible to start the bag capping process.

The same accessories and the same characteristics of Doselite can also be used for the pouchelite machinery, therefore the product can be sucked from the cooker/prepration tank, or via a loading hopper.

Of course, multiple saccasa formats can be managed, even with different spouts and caps. In the event of a format change, it will be necessary to have a capping mandrel and a bag holding fork for each format of bag/cap to be processed.

Kit and accessories

Anti-drip kits and systems

Interchangeable anti-drip systems to be combined with metering valves for volumetric feeders.

Product loading hopper

Product loading hoppers for volumetric feeders. Custom-built and configurable with numerous accessories.

Products that might interest you

Discover all the filling products similar to Pouchélite

Talk to a consultant

Need specific information about this machine? Enter your email address to be contacted by a specialized consultant